Industrial Applications of Micro Lasers

The combination of silicon materials and light emitting semiconductor materials is expected to help develop a new micro scale laser pointer, which is studied by Keh-Ting Ng Doris and colleagues at the Data Storage A*STAR Institute.

Silicon material completely changed the form of electrical equipment manufacturing. This semiconductor rich is easy to be processed into small components, such as transistors, and method which is used can be extended to the level of manufacturing industry, which makes the production of tens of thousands of components can be integrated on a single chip. Electronic engineers want to further expand the capabilities of these integrated circuits, so that they can create, process and detect light.

These optoelectronic devices can speed up the processing speed of digital information, and can realize the micro scale laser, for example, can be used in bar code scanner. The problem, however, is that the silicon material is not an effective light generator. Ng's team has designed and produced a combination of silicon and light emitting semiconductor green laser pointer, which are indium gallium arsenic compounds (InGaAsP). "Our results show that this method can achieve a high efficiency and compact active optoelectronic device for silicon substrate, that is, using a very thin III-V family of semiconductor silicon layers," Ng said.

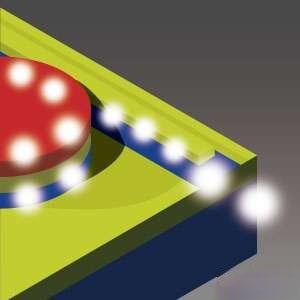

One of the important considerations in any laser structure is the ability to capture light within the structure, namely, the ability to capture light in order to further drive the generation of light. In conventional lasers, this is achieved by placing a mirror on any side of the light producing area. Instead, Ng and the team used a cylindrical geometry device. This will capture some of the light that is generated on the wall of the device and force it to spread within the cylinder. This is called whispering gallery mode, because the same effect will occur in a circular room, such as the dome of the cathedral in the sound wave.

The team started using a silicon substrate, they deposited a thin layer of silicon oxide. Thin film with optically active InGaAsP, only 210 nm thick, is individually made, and then bonded to silicon oxide. Then, the team through a number of materials to create the cylinder, with two or three microns in diameter. Three micron devices emit a 30mw laser pointer light at a wavelength of 1519 nm, which is very close to the wavelength used in commercial optical communication systems.

This device has a unique feature that extends the whispering gallery mode to the silicon and InGaAsP regions. InGaAsP can provide light amplification, and silicon can be passive guide light. "The next step, we want to apply these ideas to the devices at room temperature," Ng said. "Operation at higher temperatures will require adjustments to the design and fabrication of the laser."

http://laserman123.tsukuba.ch/e300888.html