The Relationship between Laser Surface Machining and Laser Marking

The wavelength of the laser usually belongs to the near infrared range of around 1070 nm, making it ideal for marking most metal products because the reflectivity of this wavelength is lower compared to longer CO2 lasers. But even in this wavelength range, the difficulty of marking different metals are not the same. Aluminum, copper and its alloys are widely used in almost every industry, these materials can be used red laser pointer marking, but want to heat in such conditions on the metal play clearly visible dark mark, and sometimes still difficult. In addition, a proven technique has shown that a highly transmissive material can usually be processed with a minimum damage within a pulse width that is not associated with an unexpected non-linear characteristic.

In the field of industrial laser materials processing, the term laser surface processing is often used to describe a series of continuous wave (CW), power of several kilowatts of near infrared laser source processing activities. However, the above process is completely different from the techniques described herein that can be considered as micron and nanoscale surface applications. Has been the use of short pulse picosecond and femtosecond ultrafast lasers developed many of these processes, for non-thermal mechanism on how to modify the surface processing.

The main drawback of these processes is that their investment and operating costs are still high even if they fall into the low power range of these categories of 50000mw laser pointer. Since the processing speed usually depends on the average power of the laser, the laser processing cost for actual industrial coverage is likely to be high for most industrial laser users. Recently, the range of mature nanosecond pulsed fiber lasers has been extended to sub-nanosecond, followed by an increase in the magnitude of the peak power capability. Therefore, it is possible to develop a new laser surface processing technology using a cost-effective long-picosecond laser source. Although these techniques are commonly referred to as laser microforms, these processes are mechanically related to laser marking because they are limited to the surface treatment of components and often require the use of laser ablation and melting processes.

Fiber lasers are widely known advantages to ensure that they are dominant in most applications of near-infrared 5mw green laser light source options. Of course, pulsed fiber laser sources with high average power (up to 4kW), opened the laser cleaning and laser stripping applications. The pulse duration of the new type of fiber laser used here is 0.15 ~ 5ns, the peak power is 0.5mW, the brightness is <2 per square meter, and the pulse repetition rate exceeds 1MHz under the condition of the average power up to 30W. The purpose of this paper is to improve the understanding of micrometer laser functions, which are used for surface microforms or marking, which are generally considered to be difficult to use standard infrared wavelengths for marking materials such as copper and glass.

We explored how to quantify laser marking and micro-modeling, and use these techniques to 3500mw laser pointer marking aluminum. We have also developed a technology for marking more challenging copper and uncoated surfaces, and it is clear that there will be future process applications for a wider range of surface structures. Laser welding between copper or between other metals has always been a challenge in the field of low power heat conduction welding because of the inherent high reflectivity and diffusion coefficients, as well as inconsistent primary surface oxide layers. The fact that this dark marking technology in the welding of copper, can improve consistency. As part of the ongoing study, surface finishes are improved and regulated by laser beams, which can also improve the bonding between copper or aluminum and other different metals.

In the related case, the same sub-nanosecond laser was used to laser pre-treat the metal so that it could then be bonded to the transmissive polymer. The advantages of laser cleaning surfaces, such as increased surface area due to laser pretreatment and local laser heating, facilitate the combination of specific metal-polymer combinations to easily achieve the strength level of the substrate. Finally, the use of traditional 8000mw laser pointer scanning technology on the optical surface of the diffuse or light scattering capability is guaranteed. The application being considered is to control the glare, which in turn makes the processing object easier to see for the human eye. The demonstrated performance and cost-effective introduction of fiber lasers has enabled customers to shift laser marking from low-cost applications to higher value-added marking and microforming applications.

Advantages of Laser

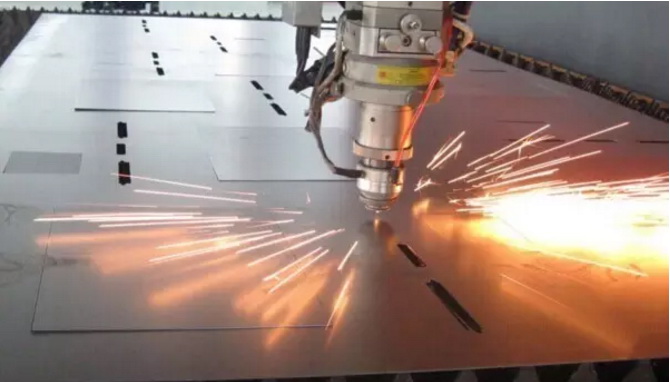

Laser processing in the application of food machinery has the following advantages: laser cutting is a non-contact processing, which is very clean, suitable for food machinery production; laser cutting of the slot is generally 0.10 ~ 0.20mm; 1w laser pointer Cutting cutting surface without burr, can cut a variety of thickness of the plate, and the truncated surface is very smooth, no secondary processing to create high-grade food machinery; speed, and effectively improve the efficiency of food machinery production; large pieces of mold manufacturing costs are high, Laser cutting without any mold manufacturing, and can completely avoid the formation of the material when the collapse of the pile, a significant reduction in production costs and improve the quality of food machinery. Once the product drawings are formed, you can immediately laser processing, in the shortest possible time to get new products in kind, effectively promote the upgrading of food machinery. Laser processing using computer programming, can be different shapes of products for the material cut, to maximize the utilization of materials, reduce the cost of food machinery production.

Laser cutting machine in the cutting process, the auxiliary gas is essential! Which we often use oxygen and nitrogen, of course, the higher the purity of the gas, the quality of cutting will be better. There are many customers want to save the cost of using air cutting, but the cutting process to protect the 3000mw green laser lens is always water mist, cutting quality is poor. The use of gas to blow away the metal slag while protecting the lens, to avoid slag attached to the lens, affecting the quality of cutting. Can effectively achieve the cutting surface smooth, no burrs without the effect of hanging dregs, are fine cut off. Can react with the material, increase the cutting speed, for example, the use of oxygen can achieve the effect of combustion.

So, in order to achieve a better cutting effect, the requirements of the auxiliary gas is relatively high! Although the air can be used as auxiliary gas, but because the air contains water and oil, if not treated, will cause the lens pollution, cutting head instability, so that the cutting effect and quality is not compliance. Therefore, in the use of air cutting, the need for fiber green astronomy laser cutting machine equipped with cold and dry machine, so that a very good solution to this problem. The cold and dry machine can be forced to cool the compressed air below the required dew point temperature, which will contain a large number of water vapor, oil mist condensed into droplets, separated by gas and liquid, drained from the drainage machine, the compressed air drying.

For the large-length metal pipe full-stroke automatic laser cutting cutting process requirements, in the mechanical structure using a unique dual-drive pneumatic chuck rotation mechanism (drive shaft W, driven shaft W1), the left side of the active shaft W-axis pneumatic chuck Rotating mechanism is fixed, the pipe clamped, through the machine X, Y, W movement of the pipe cutting, the right side of the driven shaft W1 pneumatic chuck rotation mechanism can work along the table along the workpiece axial movement, can be large Length of metal pipe full range of automatic laser cutting cutting.

CNC laser tube cutting due to high cutting efficiency, programming nesting more complex, if used improperly, it will cause waste of pipe and cutting efficiency is low. Through the professional tube cutting nesting software on the computer in advance to draw, nesting, cutting sub-programming, generate NC cutting procedures, and then large-length metal pipe full automatic burning laser pointer cutting cutting. Professional pipe material nesting software is to achieve CNC tube cutting machine large quantities, high efficiency, high-quality cutting production of the basis and prerequisites.

As the pipe cutting (especially for small diameter square pipe), the slag attached to the tube wall, cutting most of the heat generated by the workpiece absorption, cutting density is large, often lead to overheating pipe, corner and square tube four A corner burned, seriously affecting the quality of incision, or even impossible to cut. Such a problem can be used: laser cutting headband height sensing servo system to ensure that the cutting process, the cutting nozzle and the workpiece table surface height remains unchanged (focus unchanged), so that the cutting effect does not change with the workpiece surface And affected; increase the pressure of oxygen (6-8Mpa); through the software to improve the sharp angle synthesis speed.

Laser cutting technology is in the process of rapid development and continuous improvement, with the computer technology, mechanical structure, cutting technology and optimization algorithms continue to update and develop, CNC high power laser pointer cutting technology will be more prominent to show its intelligent, fast and optimized Cutting technology and skills for the laser tube cutting machine efficient cutting, high-quality cutting, as well as saving pipe and energy consumption, to provide technical assurance.

http://www.nichtraucher-blogs.de/blogs/laserman123/Air-Transmission-Process-0.html

http://laserman.blogsport.de/2017/03/11/wireless-audio-transmission-mode/

http://laserman123.mysites.nl/mypages/laserman123/550415.html

Analysis of Laser Cutting Market

Today, with the economic environment changes, laser cutting machine market demand, the brand, the competition between manufacturers has been almost white. In this regard, we are intuitive feeling is a laser cutting machine demand for new projects less, the inquiry of the people less, buy the equipment back to the difficult, long cycle, the customer was not so generous and generous, began to picky Pick these four ... ... these are "business" is not good to do the performance, if this will be "a bunch of" messy performance carried out to solve, it will make people feel at ease. However, if the current high powered laser pointer cutting machine industry competition to sum up, the main can be attributed to the brand, price and channels, as well as the service of these major aspects of competition.

Laser cutting machine brand differentiation is the purpose of the product's core strengths or personality differences into the brand to meet the individual needs of the target customer. Successful laser cutting machine brand has a differentiated characteristics, different from the competitors, and then in a consistent form of the brand differences with the customer's psychological needs to connect, in this way the brand positioning information accurately communicated to Market, in the hearts of potential customers to occupy a favorable position. The purpose is to create and develop their own characteristics of the laser cutting machine products, distinctive personality, establish a unique market image, to distinguish it from competitors, effectively determine the product in the customer's mind position. In the burning laser pen cutting machine business and products more and more homogeneous trend, similar products more and more competition more and more intense, in order to break through, companies must be selected according to the actual needs of their own brand positioning strategy, For their own businesses and products to find the right market position.

A laser cutting machine brand is well-known, can get the praise of customers, must be derived from the excellent quality and perfect service, which is the basis of the brand, there is no good quality and perfect service guarantee, no matter how good the brand will Was cast aside by the customer. This is reflected in the market for the purchase of a laser cutting machine products to customers of the brand can continue to buy and recommend to others the enthusiasm. Improve the quality of products and services is to enhance the brand's premise, it is directly related to whether it can become a real brand and brand name.

Here, competition is divided into two parts: product quality and service quality. With the rapid development of metal laser cutting machine in the Chinese market for more than ten years, the threshold of entry is rapidly decreasing, and the metal laser cutting machine is no longer mysterious, but because of the processing level of each enterprise, the manufacturing precision is different, resulting in the efficiency of each brand product , Consumption and stability, and other aspects of the show a big difference, especially compared with foreign brands, even more so. In the future of energy consumption and environmental protection, the role of product quality in market competition will become more and more significant. Services include pre-sale, sale and after-sales service, which pre-sale and sales services can be integrated as a whole, as a sales skills, which is the sales staff need to pay attention to the place. And after-sales service as a separate type of service, has been the 5000mw green laser cutting machine manufacturers, channels more and more attention. Because it is not only a continuation of the transaction services, but also a marketing ideas and ways to build their own high-end after-sales service brand is the next laser cutting machine suppliers to actively practice the direction. We can see, not only manufacturers to strengthen after-sales service, agents at all levels have a new understanding of after-sales service.

But at the same time in the after-sales service also produced a negative phenomenon, one is over-service, maintenance can repair the repair is not the whole change, small repair in the repair, repair overhaul; one is recuperation, maintenance is always The third is to grab services to low-cost, alternatives, etc. to take away the original after-sales service projects, but this type of service team maintenance work simple and brutal , Easy to make money repair items rushing, incurable diseases or due to technology is not in place caused by minor illnesses to become a serious illness disappeared without a trace. In this way, the relationship between businessmen tense, the formation of a vicious circle. Suppliers think that they sell their equipment to customers with meager profits. In addition to providing other benefits, they do not earn other profits. In the event of problems that customers can not solve, they are reluctant to provide services or improve service costs. And the customer that the equipment is their own money to buy, Moreover, the original after-sales service price and market price difference between the larger, who want him to serve who let the service, but the equipment encountered can not solve the problem, manufacturers, agents also Need to do service obligations.

The actual reason for the formation of such a contradiction is only one, that is the cost of after-sales service, that is, the price of competition, mainly reflected in the genuine and high imitation and substitutes on the price difference. In fact, the price of the 3000mw laser pointer cutting machine industry is a sensitive topic, but we can analyze what is about the price of laser cutting machine. Production and transaction costs; information asymmetry; manufacturers and channels of profits.

On the other hand, the larger the production scale, the lower the production cost, but the actual production in the laser cutting machine industry, due to the production scale of the production cost difference is not great. Due to the expansion of production scale can bring low-cost production and procurement advantages, but also bring management costs rise. In the past, large-scale production to reduce production costs are mostly based on low labor costs, but because of China's demographic dividend gradually disappear, the proportion of human resources costs in economic activity is getting heavier and heavier, while the larger, The higher the grade, the higher the investment in human resources management. In order to balance, the difference in production costs is not great, with a low-power laser cutting machine, for example, the international brand and domestic small brand cost difference of at most 1000-2000 yuan, which is priced at 20,000 yuan Laser cutting equipment is normal, because the overall price difference is also about 5,000 yuan.

By reducing the cost of production to improve brand competitiveness is the initial stage of competition, because to a certain extent, the production cost can not be infinitely compressed. In the laser cutting machine homogenization of serious today, the result of excessive crushing production costs is reduced with the quality, shoddy. This is nothing new in the laser cutting machine market. So to improve the brand premium, have to start from other aspects.

The more asymmetric the information, the greater the price change. Information asymmetry was once a major cause of 1000mw green laser cutting machine industry profits, both the objective conditions of social communication communication technology constraints, but also the manufacturers within the regional market information flow restrictions on the subjective reasons. With the gradual deepening of market-oriented information, information asymmetry is being solved, so that the laser cutting machine conventional machine and accessories prices are basically transparent. And with the Internet and other media tools publicity, brand awareness diffusion (non-customer recognition) is very easy and simple. Eliminate information asymmetry, expand the visibility can be done from the different sales channels of laser cutting machine.

http://socialnetwork.netblogger.de/five-advantages-of-laser-cutting-machine/

https://bollywoodinlondon.com/1058-mike-jack/videos/video/88-most-powerful-laser-pointer

http://forums.threetz.com/threads/laser-processing-technology.29078/

LASER WELDING TECHNIQUE FOR LARGE MATERIALS

The hydraulic system in a large laser safety room lifts 20 tons of steel and tilts to the desired angle. The green laser pointer beam and the metal active gas (MAG) will begin the laser beam and the metal-active gas (MAG). The laser beam and the metal active gas (MAG) are moved to the upper part of the device, extending the robot arm with the compound welding head, slowly across the first row of weld joints, Welding arc welding gun joint role. These solder joints are 8 mm thick and can withstand up to 320 tons of pressure. This is repeated so that the press is able to function throughout its useful life.

In the laser room, Staufer and Reiter through the monitor to observe the process. "We spent a whole week hand-welding the racks outside, and then we were determined to improve efficiency," says Reiter. "He soon discovered that laser welding is the right solution. "This welding process is much faster because we only need a welding, unlike arc welding must be completed little by little, and we can use burning laser pointer preheating material, automatic processing is also easier to ensure quality." Therefore, he will As a solution, as solution A, he also prepared a solution B - with the traditional MAG welding robot with the automatic solution. "But scenario B requires preheating and subsequent stress relief heat treatment," says Reiter, so no one wants to use Option B. But there is a big problem with Option A, as Staufer says: "We have delivered more than a hundred lasers, but the thickest sheet before is only 10mm."

Two years ago, Reiter and Staufer spent a lot of time in Vorone's research and development labs, and a series of micrographs showed that there were many small cracks and imperfections in the weldment profile, which made the weld unusable. "Eight kilowatts of brightest laser pointer power can easily penetrate 12 millimeters of material, but we have absolutely no control over the holes," Staufer recalls, "and the cracks indicate that the problem is preheating," Staufer recalls. "With laser preheat, we can fully control the parameters, but no matter how the temperature, the crack did not change."

It seemed as though Plan B had become the only option, but at one meeting, Tracy proposed the idea of fundamentally adjusting the welding strategy, and Reiter smiled and remembered: "Maybe because we just gave up on Plan A, so we Ask ourselves: do we really need that deep seam to achieve a perfectly stable interface? "So Staufer and his team of laser experts at Vorone began to gradually reduce the welding depth to 10 mm when they finally relieved , The weld quality began to improve, "in 8 mm when we finally get the ideal welding results." Staufer said.

Raimund Geh liked the challenge. His company, Femitec GmbH, is located in Gösthofen near Augsburg and specializes in welding system design. He explained his approach to the problem: "If a robot equipped with a high power laser pointer welding head can not reach the solder joint, we can replace that part of it." His idea was to use a positioner with a chuck. "We are convinced that this will allow us to weld in the flat welding position." Geh and his team developed a sophisticated simulation system to test their theory, the next step is to put it into practice. Yaskawa Europe Co., Ltd. is a leading manufacturer of drive technology, industrial automation and robotics, dedicated to transforming the company vision into reality. Otwin Kleinschmidt, head of project management, tilted the palm of his hand at a key 45 degrees, then smiled and said, "The theory is simple: the positioner plus the chucking device is just that big."

The first challenge the team encountered was to design a hydraulic system capable of withstanding several tons of weight, with a position accurate to millimeters. Kleinschmidt explained: "The only way to make the welding robot just in the welding path." Another problem is to coordinate the movement of robots and beams, but in practice 4 months later, everything finally entered the right track.

In Pasching, Staufer and Reiter began to view a variety of machine tools. They are in front of the workpiece on the tray, the crane is to help workers to the sheet metal on the table in the right place, the whole process takes two hours. This sounds complicated, but is relatively processing components, which in fact is already a very fast solution. The positioner then moves along the rail to the red laser pointer safety room. When the welding robot is in place, the worker moves to the other end of the safety room and clips the next frame onto the second workbench. "With this system, we can weld more than 20 racks per week," says Stiter. "We have been able to use this soldering process to handle different orders," says Reiter.

Laser Irradiation

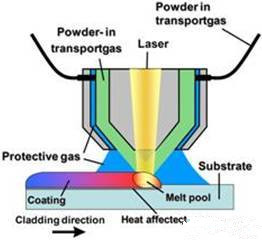

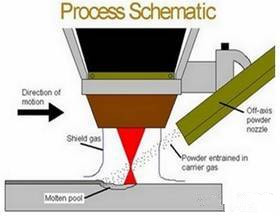

Laser cladding materials according to the way the supply of materials can be divided into two categories, namely, pre-laser cladding and synchronous laser cladding. Pre-fabricated laser cladding is to place the cladding material on the cladding surface of the base material beforehand, and then use the red laser pointer beam to irradiate and scan and melt. The cladding material is added in the form of powder, wire and plate, the most commonly used powder . The main process flow of pre-fabricated laser cladding is: pre-treatment of cladding surface of substrate material - pre-melting cladding material - preheating - laser melting - post-heat treatment. Synchronous laser cladding is to direct the cladding material into the laser beam so that the feed and cladding are completed simultaneously. Cladding material is mainly in the form of powder into, and some also use wire or sheet for synchronous feeding. Synchronous laser cladding of the main process: the substrate cladding surface pretreatment - feeding laser melting - after heat treatment.

Laser cladding refers to the different filler in the coated substrate surface placed on the surface of the selected coating material, the laser irradiation and the substrate surface of the thin layer at the same time melting and rapid solidification after dilution and extremely low and with Corrosion resistance, heat resistance, oxidation resistance and electrical characteristics of the surface of the substrate material, so as to achieve the purpose of surface modification or repair, both to meet the requirements of the surface of the substrate, On the surface of the material specific performance requirements, but also saves a lot of valuable elements.

Heat input and distortion is small, especially with high power density rapid cladding, the deformation can be reduced to the parts assembly tolerances; powder selection almost without any restrictions, especially in the melting point of low melting point metal surface alloy; The thickness of the layer of the larger, single-channel powder once the coating thickness of 0.2 ~ 2mm; can be selected cladding, material consumption less, with excellent cost performance; beam targeting can make difficult to close the region cladding, the process Easy to automate.

Laser cladding cooling speed (up to 106K / s), belonging to the rapid solidification process, easy to get fine grain structure or produce equilibrium can not get a new phase, such as unsteady phase, amorphous, etc .; coating dilution rate is low (Usually less than 5%), and the matrix was solid metallurgical bonding or interface diffusion combination of the cheap laser pointer process parameters can be obtained by a low dilution of a good coating, and coating composition and dilution controllable.

UHT is the ultra-high temperature instantaneous sterilization, milk is a common sterilization process, by maintaining the milk at 135 to 140. In addition to the milk, ℃ between 4 ~ 10s and then quickly cooled for sterilization, does not affect the nutrition and flavor of milk, but also greatly extend the shelf life of milk at room temperature. In fact, in the field of aviation manufacturing, there is also the idea of the existence of technology. Through a short period of processing, does not affect the material good performance, but also extend the service life, which is laser cladding.

The greater the burning laser pointer power, the greater the amount of molten cladding metal, the greater the probability of porosity. With the increase of laser power, the depth of cladding increases, and the surrounding liquid metal fluctuates violently. The solidification and crystallization of the liquid metal gradually reduce or even eliminate the number of pores and reduce the crack. When the cladding depth reaches the limit depth, as the power increases, the substrate surface temperature increases, deformation and cracking increased. Laser power is too small, only the surface coating melts, the matrix is not melting, this time the cladding surface of the local pilling, holes, etc., reach the purpose of surface cladding.

Laser beam is generally circular, cladding width depends on the laser beam spot diameter, spot size increases, cladding layer widened. The difference of spot size caused the change of the energy distribution of the cladding layer, and the morphology and microstructure of the cladding were different. Generally speaking, in the small size spot, the cladding quality is better; with the spot size increases, the cladding quality. But the spot diameter is too small, not conducive to large area of the cladding.

The ceramic coating can be prepared by laser method. The ceramic coating can be pre-coated on the metal surface, and then laser treatment is carried out to make the coating structure more fine. (Such as NiCr, NiAl, NiCrAl, Mo, etc.) materials, and then coated with ceramic laser pulse material, the filter layer Ni, Cr alloy and ceramic Al2O3, ZrO2 attached to the Substrate surface, the formation of porous properties, so that the matrix of metal molecules can also spread to the ceramic, thereby improving the coating structure and performance.

Laser cladding technology enables the rapid preparation of complex metal parts of different materials without the need for any rigid mold or mold. This technology breaks the conventional mechanical manufacturing concept and enables the creation of complex metal solid parts of arbitrary shape , The complexity of the shape of parts of the adaptability is very strong, for the manufacture of complex parts provides an effective way.The cladding speed and 2000mw laser pointer power have similar effects. Cladding speed is too high, the alloy powder can not be completely melted, can not play the role of high-quality cladding; cladding speed is too low, the pool exists for too long, the powder burned, alloying elements loss, while the substrate heat input is too large, Will increase the amount of deformation.

The aerospace industry is rapidly adopting newer alloys such as Ti-6Al-4V to produce high strength / weight ratios, heat, fatigue and corrosion resistant parts. However, in these new alloy processing, the traditional process has many difficult to overcome the shortcomings, such as the production of partitions is several inches thick thousands of pounds of tooth-shaped alloy plate processing, the time to get these alloy plates to one year or one Year or more. Because it is difficult to process, machining such parts requires expensive machining centers for hundreds of hours and wears large amounts of cutting tools. And green laser pointer cladding technology in this area has a greater advantage, you can reduce inventory and reduce manufacturing time.

Laser cladding technology has a direct impact on the current repair process, and its advantages include process automation, low thermal stress and deformation, and so on. As the life expectancy of aircraft is expected to increase, more complex repair and repair processes are required. Parts such as turbine blades, impellers, and rotating air gaskets are part of a process that can extend the life of existing structures. Some of these parts can be repaired by surface hardening, but many other parts require more complex repair processes, Processed material. Laser cladding repair process can be applied to a wide range of materials without reducing the performance of base metal, parts or tools than the replacement of more than 75% cost savings.

With the development of aviation gas turbines to the high flow ratio, high thrust-weight ratio and high inlet temperature, the gas temperature and pressure in the combustion chamber have been increasing. Ceramic thermal barrier coating for gas turbine superalloy surface, play a role in insulation, can reduce the metal surface temperature, improve the gas temperature, thereby enhancing the gas turbine efficiency and extend its service life. The ceramic or metal powder is directly irradiated by high power laser pointer, melted and solidified on the metal substrate to form a coating. The ceramics and the metal matrix are metallurgically bonded to obtain a columnar structure perpendicular to the surface and form a good thermal barrier coating.

Laser Rapid Prototyping Technology

The use of laser through the interaction with the material, according to certain requirements of the processing or molding, collectively referred to as light manufacturing. Nearly 20 years, light manufacturing technology has penetrated into the high-tech fields and industries, and began to replace or transform some of the traditional processing industry. In the developed countries of the automotive industry, 50% -70% of the parts is completed by laser processing. Light manufacturing technology to improve the automotive industry R & D and manufacturing level, is playing an increasingly important role.

At present, the light source used in the light manufacturing technology is mainly laser, the high power laser pointer beam has the characteristics of high energy density, high single-palladium and high directivity, which makes the optical manufacturing technology has many advantages over the traditional manufacturing technology. The tool used in this technology is the "laser knife", no tool wear during machining; no effect of cutting force on the workpiece during machining, so the workpiece without cold processing deformation; due to high energy injection processing time, the workpiece heat is small, The laser has good spatial control (direction change, rotation, scanning, etc.) and time control (open) of the laser beam, which can not be processed by the conventional technology. , Off, pulse interval), particularly suitable for automated processing, large-scale manufacturing in the production of high efficiency; laser processing of the object material, shape, size and processing environment are great freedom; low noise, does not produce harmful rays and Residue, the production process of environmental pollution is small; can save molds, shorten product development cycle and reduce development costs; material waste, in large-scale production of low manufacturing costs.

Laser manufacturing, laser drilling, laser marking and laser cutting are the key technologies for light manufacturing. No cutting stress, no cutting burr; high precision, good repeatability, do not damage the surface of the workpiece. The cutting edge is smooth, smooth cutting edge, cutting edge parallelism, no procurement follow-up processing; Laser drilling speed, high efficiency, suitable for large quantities of high-density group of holes processing; green laser pointer drilling can obtain a large aspect ratio can be hard, brittle, soft and other materials for processing, and even in the Difficult to process materials on the inclined plane processing holes; laser drilling process clean, non-polluting. Laser marking is a non-contact marking, fast, easy to wear mark, laser marking machine and very easy to combine with the assembly line. Laser cutting is similar to machining in a process of milling, it is the use of focused laser beam to cut the material layer by layer.

Laser welding is the use of high-intensity laser beam will be welded to the local melting temperature of molten metal fusion welded joints made of the process. Can weld high-melting point metal, non-metal, composite materials and other special materials, but also to achieve dissimilar materials and special welding structure welding; weld with "self-purification" effect, high quality weld; can be accurate welding, generally do not need Filling the metal; through the light guide system so that the laser beam and a number of devices constitute a flexible processing system, welding a high degree of automation, high production efficiency; high-energy beam welding, laser welding is characterized by the largest vacuum chamber does not produce x-ray .

Laser surface hardening is divided into two laser pointer hardening and laser melting hardening. Laser phase transformation hardening, also known as laser quenching, it is a high-energy laser beam rapid scanning of the workpiece, so that the surface temperature of the irradiated metal or alloy to a very fast rate to the point above the laser beam from the irradiated parts, Due to heat conduction, in the cold state of the matrix to rapidly cooling and self-quenching, get a smaller layer of hardened layer, the hardness is generally higher than the conventional quenching hardness; laser melting hardening process similar to the previous process, the difference is that the laser The surface of the material heating temperature is higher, the final part of the surface to form a layer of tissue flame hardening layer. Laser welding is the use of high-energy laser beam irradiation of the cladding material, with the substrate surface layer with rapid melting, forming with the substrate metallurgy with completely different composition and performance of the alloy coating.

Light rapid prototyping technology principle is under the control of the computer, CAD and other parts of the design model and data, the burning laser pointer beam will be forming material layer by layer curing, from the point and line structure parts of the surface (layer), the surface accurate accumulation of three-dimensional Solid model or part of the process. The use of light rapid prototyping technology, can significantly shorten the product development cycle, greatly reduce development costs, can quickly produce products to adapt to market changes, maintain and enhance the competitiveness of products in the market. At the same time, the use of optical rapid prototyping technology is also to achieve concurrent engineering and agile manufacturing effective technical approach.

Laser into OLED TV Real Opponent

TV competition increasingly fierce, the original OLED TV was high hopes, but after several years of development, OLED TV price is still not down to earth, and with the development of quantum dot technology as well as the declining price of LCD TV, OLED TV can be said that the development speed of a straight lift up, then later faced the competition will be more and more. Now laser pointer TV appeared, the opponent can not be underestimated.

Compared to OLED TV, laser TV in color and life is not much difference, and there is a clear advantage in size. OLED is a natural lighting technology, there is no backlight restrictions, products can be done more thin. In addition there are a lot of advantages, such as the development of the LCD panel for many years to improve the wide range of visual technology, OLED panel will support a wide range of natural perspective. In terms of color OLED panel also has a natural advantage, so OLED panel has been given great expectations. But the cost of the OLED panel is very high, although there has been $55 of 1500 inches OLED TV, but overall, the price of OLED TV is still high.

In the high price of this feature, OLED TV and burning laser pointer TV is very similar. Laser TV is actually the projector, the projector with reflective ultra short focus technology, at a distance of 0.4 meters to 100 inch projection screen, with anti screen use, the effect is very good. Even the night light conditions, the brightness of the screen can also meet the general household. Of course, during the day, the brightness of the laser TV is still not compared with the OLED tv. Laser TV price is relatively high, want to buy TV and anti laser screen, a set of basic down to $4000.

At present, OLED TV prices fell a little faster, at least has reached twenty thousand yuan, but note that reached twenty thousand yuan OLED TV size is only 55 inches, and this size compared to the LCD TV does not take advantage of what. Currently 55 inch LCD TVs may only need $500 to be able to buy. So the basis of the introduction of the user will buy LCD TV, and the pursuit of the user how to choose not to say. From both the price point of view, it is likely that the future price gap between the two will not be great. After all, the price category OLED TV also don't want to go into the LCD TV to set off a price war, OLED TV may or high-end market positioning; and happen to be the high power laser pointer TV is positioned in the high-end market.

From the upstream industry, OLED panel production cost is more high, because the OLED panel industry needs more funds, production more complex; laser TV is composed of light source and basic machine, currently has a light source part of enterprises to realize the independent research and development, the future is likely to cut prices, while the core of the display chip while still by foreign control, but with the growth of the market, the upstream chip enterprises will not remain high. It is expected that the price of laser TV is faster than the OLED TV, which has a relationship with the characteristics of the technology.

From the essence of the product, the OLED TV and laser TV color are good, and the service life is no problem. The material life of the OLED panel can be supported for five or six years, and the laser light source can meet the requirements of tens of thousands of hours to meet the general household use. OLED TV has the advantage of strong anti light ability, daytime viewing effect is not too big problem; while the advantage of laser TV is large size, the evening can easily achieve more than 100 inches large screen.

So the user's needs are different, the views of the two devices are different, like a big picture of a friend, you will tend to choose a green laser pointer TV; and more traditional users may choose OLED tv. As for the OLED eye and the advantages of good color, but also have the same resolution of laser TV, both can achieve the effect of 4K, and OLED TV and laser TV are available with intelligent systems, we can only say that the two are different characteristics of the product, if you really want more than a compete is very difficult. OLED TV and laser TV is the target population have some overlap, the future must have a market to fight. At present, the two are rarely used to compare, this is because the development of the track is not coincident with each other, two years later, it is likely that the OLED TV and laser TV will come to a head-on confrontation.

At present, many brands have entered the laser TV, LCD TV brands such as Hisense and Changhong traditional, and also have the new Internet companies such as nuts and so on, as well as traditional TV brands have launched a laser projector. Many brands to join, will make the concept of 3w green laser TV for more consumers to understand. At present, the popularity of OLED TV is still greater than the laser tv. For this new product of laser TV, a lot of consumer awareness is not very clear. From the perspective of the development of large screen display products, the future of OLED TV competition is indeed a lot of LCD TV, traditional TV, laser also has such new products, two competitors each have their own advantages: traditional LCD TV prices low, to meet the entry of the user, and the laser can meet the large TV screen, the needs of high-end users, so OLED TV is facing the pressure of competition is not small.

With the reduction of the cost of OLED, its application in the small screen but there is no great potential; whether it is a mobile phone or laptop or display, it can be said that the OLED panel are really competitive, not for the laser TV market, while the LCD panel technical advantages in the market is not so strong in OLED. OLED light, energy saving and good color advantages, will help its small size panel market has a good prospect. It is a large screen market, if you want to do 80 inch or 100 inch OLED panel, the price is too high, no method and green astronomy laser TV competition; while in the traditional 55 inch OLED TV market, really want to kill and LCD TV prices? To know the price of the LCD panel but after many years to reduce to now the degree of. Recently, Apple's next generation mobile phone fancy OLED panel news continues to burst, which also shows that the future of OLED panel from the side of small size.